Cable Li02Y(St)C11Y CanBUS - sect. 1x2x0.34mm² - Braid Shield –

PUR jacket O.D. 7.00mm - AWM Style 20236 (80°C / 30V)

CODE : 86A22T1201-E30

Homologation UL AWM style: 20236

Homologation UL AWM style: 20236

Accordance to Directives: 2014/35/UE; 2014/30/UE; 2011/65/CE; 2015/863/UE

Accordance to Directives: 2014/35/UE; 2014/30/UE; 2011/65/CE; 2015/863/UE

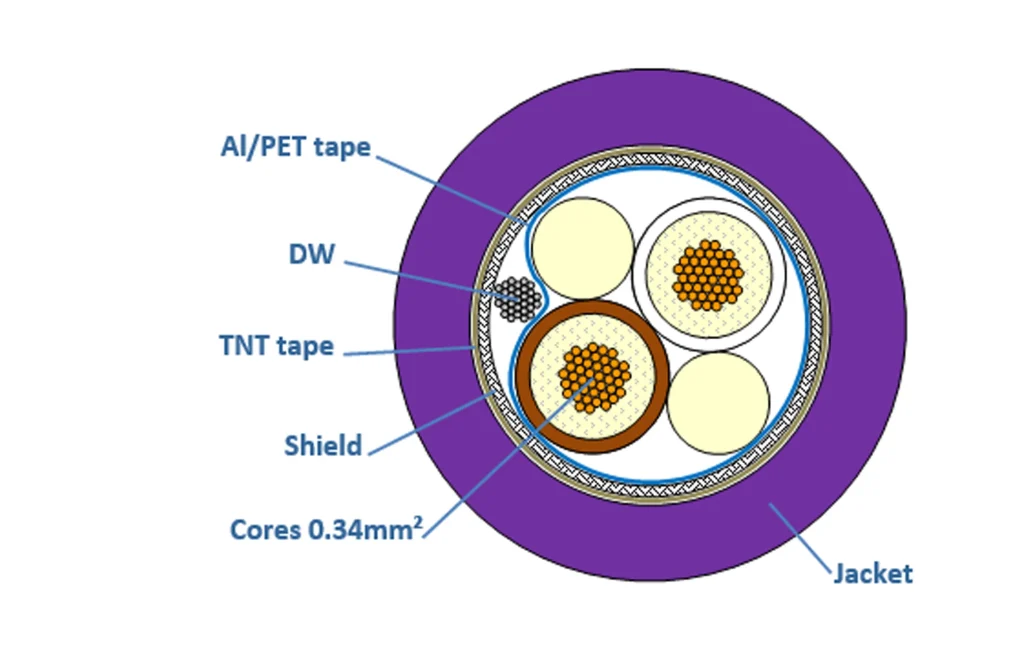

GENERAL CONSTRUCTION

Conductor

Stranded Bare copper wire; nom. 0.34mm² - AWG22; nominal diameter 0.80mm; cl.6 VDE0295;

Lay agree with UL 758 tab 5.9; Conform to EN 13602 - ETP1, DIN 40500 E-Cu 58.

Insulation

Foam PE (with internal and external skin); Nominal diameter 2.10mm; Colour cores: White – Brown.

Assembly

Two cores twisted together with fillers in gap (see indicative sketch).

Shield

First: Al/PET tape over assembly (Aluminium face outside); Optical coverage 100%.

Second: Braid type; Tin copper wire 0.10mm; nominal optical coverage 80%.

Drain wire: Stranded Tin copper wire 0.25mm² (AWG24); DW under braid shield.

Protective tape:

Nonwovens tape (TNT) over total shield.

Jacket:

PUR, hardness 92 ShA; diameter 7.00 ±0.30mm; colour Violet similar RAL4001; conform to UL AWM Style20236.

TECHNICAL DATA

Electrical

Operating voltage 30V

Voltage test 1000 V x 1min

Max conductor resistance 61.6 Ω/Km

Impedance 120 Ω ± 10%

Nominal Capacitance @1KHz: 40 pF/m

Chemical

Oil resistance - yes (Oil Res I – UL758)

Free of FCKW, Silicone and Pb - yes

Halogen free - yes (CEI EN 60754-1 / VDE 0482-754-1)

Physical

Operating temperature range -40°C to +80°C (fixed)

Operating temperature range -30°C to +80°C (free motion without periodic recurrence and forced guidance)

Bending radius >10 x OD (fixed)

Bending radius >15 x OD (Flex and drag chain)

UV resistant - yes (UL1581)

Flame

Flame resistant

UL Cable Flame test; CSA FT1; IEC 60332-1;

Movement data @20°C:

Acceleration: up to 10 m/sec²

Speed: up to 200 m/min

Torsion: ±30° (Optimal recommended)

Cavi BUS e DATI questa tipologia di cavi viene utilizzata per gestire la trasmissione dati per sistemi complessi dove si richiedono valori di impedenza e velocità di trasmissione. Sono disponibili due gamme di prodotti per posa dinamica o posa statica, in rispondenza alle omologazioni UL, CSA e DESINA.